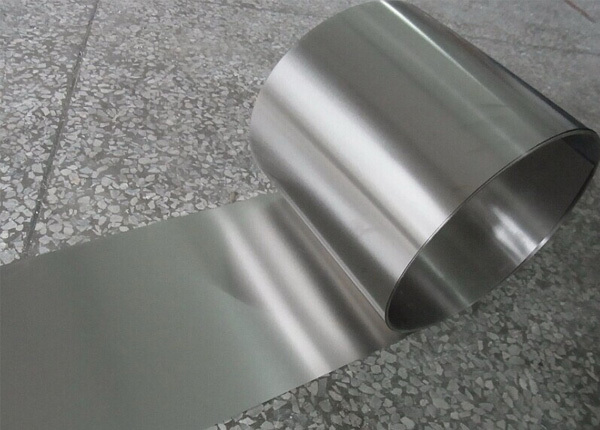

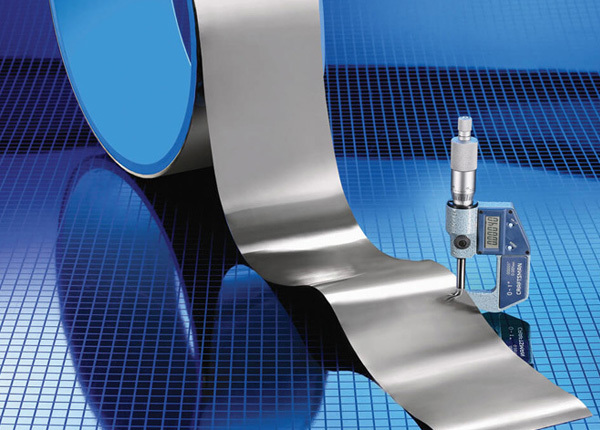

The specimens of skinny strip have been uncovered to the take a look at temperature in 50-hour cycles with weight reduction decided after every cycle. The fantastic resistance of this Stainless Steel WNR 1.4449 Plates to oxidation in fact outcomes from the alloy’s chromium and aluminium contents. At accelerated temperatures, the ones factors motive the formation of a thin, subsurface quarter of oxide particles. The oxide quarter presents the right diffusion situations for the formation of a defensive chromium oxide layer at the surface of the metal. The assessments have been completed on specimens of skinny strip and consisted of cycles of publicity to temperature for 15 mins accompanied with the aid of using cooling in nonetheless air for five mins. The outcomes exhibit the ability of this 317 Stainless Steel Sheets to shape and keep defensive surface oxide beneath situations of extraordinarily intense thermal cycling.

It additionally enables to save you spalling of the protecting layer. Stainless Steel UNS S31703 Plates are carburization-resistant alloys in gaseous carburizing surroundings at 2000 Degree F (1095 Degree C). The weight-benefit measurements imply the quantity of carbon absorbed in the course of the take a look at period. It suggests the prevalence of this Stainless Steel WNR 1.4438 Sheets of similar strength in a gas-carburization take a look at 1800 Degree F (980 Degree C). While this alloy reveals fantastic resistance to aqueous corrosion with the aid of using many media, the alloy is typically most effective used at excessive temperatures. 317L Stainless Steel Plates has precise fabricability. And so, Forming, machining, and welding are performed with the aid of using standard processes for nickel alloys. Techniques and system for a few operations can be inspired with the aid of using the alloy’s strength and work-hardening rate.